Intro

Boost efficiency at Anaheim CA distribution centers with these 7 expert strategies. Discover how optimized warehouse layout, inventory management software, and streamlined logistics can reduce costs and enhance productivity. Learn how to leverage technology, staffing, and supply chain optimization to stay ahead in the competitive world of distribution and fulfillment.

Anaheim, California, has become a hub for distribution centers due to its strategic location and favorable business climate. As the demand for efficient and effective logistics continues to grow, Anaheim's distribution centers are adopting innovative strategies to stay ahead of the curve. In this article, we will explore seven ways Anaheim's distribution centers are boosting efficiency and revolutionizing the industry.

1. Implementing Automation and Robotics

Anaheim's distribution centers are increasingly adopting automation and robotics to streamline their operations. By leveraging cutting-edge technologies such as artificial intelligence, machine learning, and the Internet of Things (IoT), these centers are able to optimize their workflows, reduce manual labor, and increase productivity. For instance, automated storage and retrieval systems (AS/RS) enable faster and more accurate picking and packing, while robotic process automation (RPA) helps with tasks such as data entry and inventory management.

Benefits of Automation and Robotics

- Increased efficiency and productivity

- Reduced labor costs and improved accuracy

- Enhanced customer satisfaction and faster order fulfillment

2. Optimizing Warehouse Layout and Design

A well-designed warehouse layout is crucial for efficient distribution center operations. Anaheim's distribution centers are optimizing their warehouse layouts to minimize walking distances, reduce congestion, and improve visibility. By implementing strategies such as zone picking, batch picking, and dynamic slotting, these centers are able to reduce labor costs, improve inventory management, and increase order fulfillment rates.

Benefits of Optimized Warehouse Layout

- Improved inventory management and reduced stockouts

- Increased order fulfillment rates and reduced shipping times

- Enhanced employee safety and reduced labor costs

3. Leveraging Data Analytics and Insights

Data analytics and insights are playing an increasingly important role in distribution center operations. Anaheim's distribution centers are leveraging data analytics tools to gain visibility into their operations, identify areas for improvement, and optimize their workflows. By analyzing data on inventory levels, order volumes, and shipping patterns, these centers are able to make informed decisions, reduce costs, and improve customer satisfaction.

Benefits of Data Analytics and Insights

- Improved inventory management and reduced stockouts

- Increased order fulfillment rates and reduced shipping times

- Enhanced customer satisfaction and improved supply chain visibility

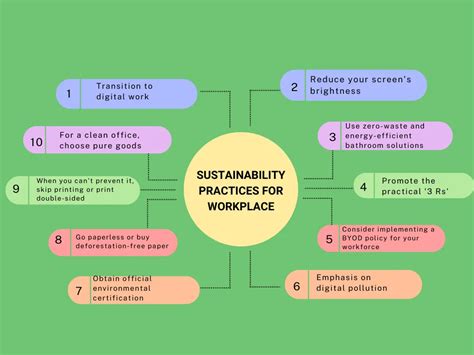

4. Implementing Sustainable Practices

Anaheim's distribution centers are recognizing the importance of sustainability in their operations. By implementing sustainable practices such as energy-efficient lighting, solar panels, and rainwater harvesting, these centers are reducing their environmental impact, lowering their energy costs, and improving their brand reputation.

Benefits of Sustainable Practices

- Reduced environmental impact and improved brand reputation

- Lower energy costs and improved operational efficiency

- Enhanced employee morale and reduced turnover rates

5. Fostering a Culture of Continuous Improvement

Anaheim's distribution centers are fostering a culture of continuous improvement to stay ahead of the competition. By encouraging employee feedback, providing training and development opportunities, and recognizing and rewarding innovation, these centers are able to identify areas for improvement, implement process improvements, and drive innovation.

Benefits of Continuous Improvement

- Improved employee engagement and reduced turnover rates

- Increased innovation and process improvements

- Enhanced customer satisfaction and improved supply chain visibility

6. Investing in Employee Training and Development

Anaheim's distribution centers are recognizing the importance of employee training and development in driving efficiency and productivity. By providing regular training and development opportunities, these centers are able to improve employee skills, knowledge, and engagement, reducing errors, and improving customer satisfaction.

Benefits of Employee Training and Development

- Improved employee skills, knowledge, and engagement

- Reduced errors and improved customer satisfaction

- Increased innovation and process improvements

7. Building Strategic Partnerships

Anaheim's distribution centers are building strategic partnerships with suppliers, carriers, and other stakeholders to drive efficiency and productivity. By collaborating with partners, these centers are able to reduce costs, improve supply chain visibility, and enhance customer satisfaction.

Benefits of Strategic Partnerships

- Reduced costs and improved supply chain visibility

- Enhanced customer satisfaction and improved order fulfillment rates

- Increased innovation and process improvements

In conclusion, Anaheim's distribution centers are boosting efficiency and productivity by implementing automation and robotics, optimizing warehouse layout and design, leveraging data analytics and insights, implementing sustainable practices, fostering a culture of continuous improvement, investing in employee training and development, and building strategic partnerships. By adopting these strategies, distribution centers in Anaheim are able to stay ahead of the competition, improve customer satisfaction, and drive innovation in the industry.

What are the benefits of automation and robotics in distribution centers?

+Automation and robotics can improve efficiency and productivity, reduce labor costs and improve accuracy, and enhance customer satisfaction and faster order fulfillment.

How can data analytics and insights improve distribution center operations?

+Data analytics and insights can improve inventory management and reduce stockouts, increase order fulfillment rates and reduce shipping times, and enhance customer satisfaction and improve supply chain visibility.

What are the benefits of sustainable practices in distribution centers?

+Sustainable practices can reduce environmental impact and improve brand reputation, lower energy costs and improve operational efficiency, and enhance employee morale and reduce turnover rates.

We hope this article has provided valuable insights into the ways Anaheim's distribution centers are boosting efficiency and productivity. If you have any questions or comments, please feel free to share them below.