Intro

Boost hospital productivity with optimized Central Sterile Supply Department (CSSD) efficiency. Discover expert strategies for streamlining sterilization processes, improving instrument tracking, and enhancing patient safety. Learn how to reduce costs, increase efficiency, and meet regulatory standards, ensuring your CSSD operates at peak performance.

The Central Sterile Supply Department (CSSD) is a critical component of any healthcare facility, responsible for the sterilization, storage, and distribution of medical equipment and supplies. Optimizing CSSD efficiency is essential to ensure patient safety, reduce healthcare-associated infections, and maintain high-quality care. In this article, we will explore the importance of CSSD efficiency, its benefits, and provide practical strategies for optimizing CSSD operations.

Understanding the Importance of CSSD Efficiency

CSSD efficiency is crucial for several reasons. Firstly, it ensures that medical equipment and supplies are sterilized and available when needed, reducing the risk of healthcare-associated infections. Secondly, efficient CSSD operations help reduce costs by minimizing waste, optimizing resource utilization, and streamlining workflows. Finally, CSSD efficiency contributes to improved patient outcomes by ensuring that medical staff have access to the necessary equipment and supplies to provide high-quality care.

Benefits of Optimizing CSSD Efficiency

Optimizing CSSD efficiency offers numerous benefits, including:

- Improved patient safety through reduced risk of healthcare-associated infections

- Enhanced quality of care through timely availability of sterilized equipment and supplies

- Reduced costs through minimized waste, optimized resource utilization, and streamlined workflows

- Increased staff productivity and morale through efficient workflows and reduced workload

- Improved compliance with regulatory requirements and industry standards

Strategies for Optimizing CSSD Efficiency

To optimize CSSD efficiency, healthcare facilities can implement the following strategies:

Standardize Processes and Workflows

Standardizing processes and workflows helps reduce variability, improves consistency, and increases efficiency. This can be achieved by:

- Developing and implementing standardized operating procedures (SOPs)

- Establishing clear workflows and protocols for equipment sterilization, storage, and distribution

- Providing ongoing training and education to staff on standardized processes and workflows

Implement a Lean Management System

A Lean management system helps identify and eliminate waste, optimize resource utilization, and streamline workflows. This can be achieved by:

- Conducting value stream mapping to identify areas of waste and inefficiency

- Implementing process improvements and waste reduction strategies

- Establishing a culture of continuous improvement and employee empowerment

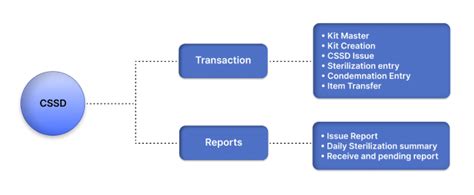

Invest in Technology and Automation

Investing in technology and automation can help streamline workflows, improve efficiency, and reduce errors. This can be achieved by:

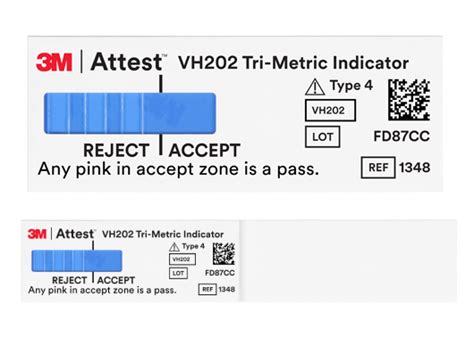

- Implementing automated sterilization and packaging systems

- Utilizing barcode scanning and tracking systems to monitor equipment and supplies

- Implementing electronic documentation and record-keeping systems

Enhance Staff Training and Education

Enhancing staff training and education is critical for optimizing CSSD efficiency. This can be achieved by:

- Providing ongoing training and education on standardized processes and workflows

- Offering certification programs for staff to demonstrate competence and expertise

- Encouraging continuous learning and professional development

Measuring and Evaluating CSSD Efficiency

To evaluate the effectiveness of CSSD efficiency optimization strategies, healthcare facilities can use the following metrics:

- Sterilization cycle times and throughput

- Equipment and supply availability and utilization rates

- Staff productivity and workload metrics

- Patient satisfaction and outcome metrics

- Compliance with regulatory requirements and industry standards

Best Practices for CSSD Efficiency

To achieve optimal CSSD efficiency, healthcare facilities can adopt the following best practices:

- Establish a culture of continuous improvement and employee empowerment

- Implement standardized processes and workflows

- Invest in technology and automation

- Enhance staff training and education

- Regularly evaluate and measure CSSD efficiency metrics

What are the benefits of optimizing CSSD efficiency?

+Optimizing CSSD efficiency offers numerous benefits, including improved patient safety, enhanced quality of care, reduced costs, and increased staff productivity and morale.

What strategies can be implemented to optimize CSSD efficiency?

+Strategies for optimizing CSSD efficiency include standardizing processes and workflows, implementing a Lean management system, investing in technology and automation, and enhancing staff training and education.

How can CSSD efficiency be measured and evaluated?

+CSSD efficiency can be measured and evaluated using metrics such as sterilization cycle times and throughput, equipment and supply availability and utilization rates, staff productivity and workload metrics, patient satisfaction and outcome metrics, and compliance with regulatory requirements and industry standards.

In conclusion, optimizing CSSD efficiency is critical for ensuring patient safety, reducing healthcare-associated infections, and improving the quality of care. By implementing strategies such as standardizing processes and workflows, investing in technology and automation, and enhancing staff training and education, healthcare facilities can optimize CSSD efficiency and achieve improved patient outcomes.

We hope this article has provided valuable insights into the importance of CSSD efficiency and the strategies for optimizing it. Share your thoughts and experiences on CSSD efficiency optimization in the comments section below.