Intro

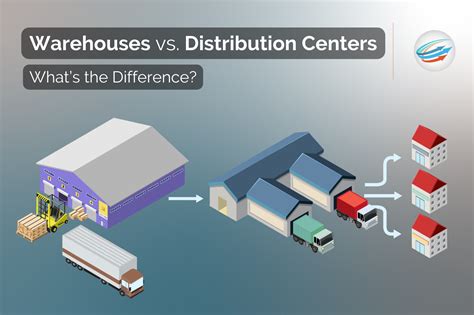

Boost efficiency and productivity at your City of Industry, CA distribution center with these 5 expert optimization strategies. From streamlining warehouse management to implementing smart logistics solutions, discover how to reduce costs, enhance supply chain visibility, and increase customer satisfaction in the heart of Southern Californias industrial hub.

As a business owner, optimizing your distribution center in City of Industry, CA, is crucial for improving efficiency, reducing costs, and enhancing customer satisfaction. With the rise of e-commerce and increasing demand for fast and reliable shipping, having a well-organized and streamlined distribution center is more important than ever. In this article, we will explore five ways to optimize your City of Industry, CA, distribution center.

Understanding Your Distribution Center's Challenges

Before we dive into the optimization strategies, it's essential to understand the common challenges faced by distribution centers in City of Industry, CA. These challenges include:

- Inefficient use of space and labor

- High transportation costs

- Inaccurate inventory management

- Poor communication between teams

- Inability to adapt to changing market demands

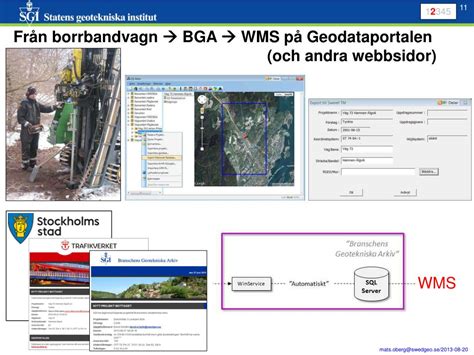

Optimization Strategy 1: Implement a Warehouse Management System (WMS)

A WMS is a software solution that helps manage and control the day-to-day operations of your distribution center. It provides real-time visibility into inventory levels, tracks shipments, and optimizes storage and picking processes. By implementing a WMS, you can:

- Improve inventory accuracy and reduce stockouts

- Increase picking and packing efficiency

- Enhance customer satisfaction with faster and more accurate shipments

- Reduce labor costs and improve productivity

Benefits of a WMS

- Improved inventory management

- Increased efficiency and productivity

- Enhanced customer satisfaction

- Reduced labor costs

Optimization Strategy 2: Optimize Your Warehouse Layout

Your warehouse layout plays a critical role in determining the efficiency of your distribution center. A well-designed layout can help reduce walking distances, improve picking and packing rates, and increase storage capacity. Consider the following layout optimization strategies:

- Implement a zone picking system to reduce walking distances and improve picking rates

- Use vertical storage solutions to maximize storage capacity

- Designate specific areas for receiving, storage, and shipping to improve workflow and reduce congestion

Benefits of an Optimized Warehouse Layout

- Improved picking and packing rates

- Increased storage capacity

- Reduced walking distances and labor costs

- Improved workflow and reduced congestion

Optimization Strategy 3: Implement a Transportation Management System (TMS)

A TMS is a software solution that helps manage and optimize your transportation operations. It provides real-time visibility into shipment status, tracks carrier performance, and optimizes routes and rates. By implementing a TMS, you can:

- Reduce transportation costs and improve carrier performance

- Improve shipment visibility and tracking

- Enhance customer satisfaction with faster and more reliable shipments

- Reduce the risk of delays and lost shipments

Benefits of a TMS

- Reduced transportation costs

- Improved shipment visibility and tracking

- Enhanced customer satisfaction

- Reduced risk of delays and lost shipments

Optimization Strategy 4: Improve Inventory Management

Effective inventory management is critical to the success of your distribution center. Consider the following strategies to improve your inventory management:

- Implement a just-in-time (JIT) inventory system to reduce stock levels and improve inventory turnover

- Use data analytics to optimize inventory levels and reduce stockouts

- Implement a cycle counting program to improve inventory accuracy and reduce errors

Benefits of Improved Inventory Management

- Reduced stock levels and improved inventory turnover

- Improved inventory accuracy and reduced errors

- Reduced stockouts and overstocking

- Improved customer satisfaction

Optimization Strategy 5: Invest in Employee Training and Development

Your employees are the backbone of your distribution center. Investing in their training and development is essential to improving efficiency, productivity, and customer satisfaction. Consider the following strategies:

- Provide ongoing training and development programs to improve skills and knowledge

- Implement a performance-based incentive program to motivate employees

- Encourage employee feedback and suggestions to improve processes and procedures

Benefits of Employee Training and Development

- Improved efficiency and productivity

- Enhanced customer satisfaction

- Reduced errors and improved quality

- Improved employee morale and retention

By implementing these five optimization strategies, you can improve the efficiency, productivity, and customer satisfaction of your City of Industry, CA, distribution center. Remember to continuously monitor and evaluate your operations to identify areas for further improvement.

What is a Warehouse Management System (WMS)?

+A WMS is a software solution that helps manage and control the day-to-day operations of a distribution center.

How can I optimize my warehouse layout?

+Consider implementing a zone picking system, using vertical storage solutions, and designating specific areas for receiving, storage, and shipping.

What is a Transportation Management System (TMS)?

+A TMS is a software solution that helps manage and optimize transportation operations, providing real-time visibility into shipment status and tracking carrier performance.

We hope this article has provided you with valuable insights and strategies to optimize your City of Industry, CA, distribution center. Share your thoughts and experiences in the comments below, and don't forget to share this article with your colleagues and friends.