Intro

Improve product reliability with the Load and Shift Test. This guide explains the reliability analysis method, its benefits, and how to apply it to enhance product performance. Learn about accelerated testing, reliability metrics, and real-world applications to ensure your products withstand stress and last longer.

Load and shift tests are crucial components of reliability analysis, enabling engineers to assess the performance and durability of mechanical systems, structures, and components under various operating conditions. These tests help identify potential failures, optimize system design, and ensure the overall reliability and safety of the system. In this article, we will delve into the world of load and shift tests, exploring their significance, types, procedures, and applications.

Understanding Load and Shift Tests

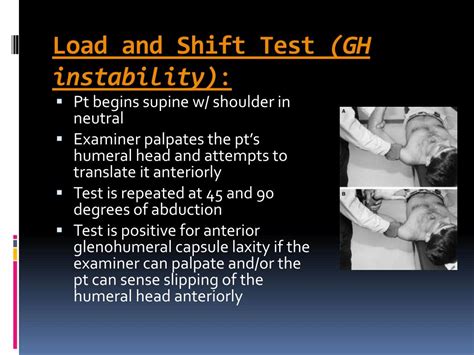

Load and shift tests are designed to simulate real-world operating conditions, subjecting the system or component to various loads, stresses, and environmental factors. These tests aim to evaluate the system's ability to withstand and recover from these stresses, providing valuable insights into its reliability, durability, and performance.

Types of Load and Shift Tests

There are several types of load and shift tests, each with its own specific objectives and applications:

- Static Load Test: This test involves applying a constant load to the system or component to assess its ability to withstand stress and deformation.

- Dynamic Load Test: This test simulates real-world operating conditions by applying varying loads, frequencies, and amplitudes to the system or component.

- Shift Test: This test evaluates the system's ability to withstand sudden changes in load, stress, or environmental conditions.

- Cyclic Load Test: This test involves applying repeated loads to the system or component to assess its fatigue life and durability.

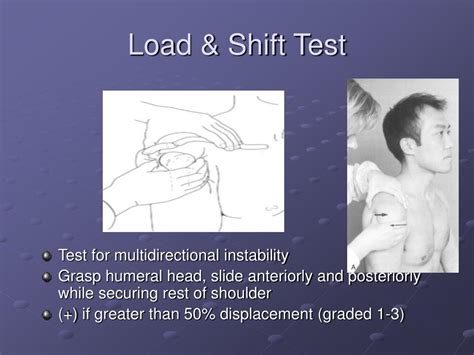

Procedures for Load and Shift Tests

Conducting load and shift tests requires careful planning, preparation, and execution. The following procedures outline the general steps involved in these tests:

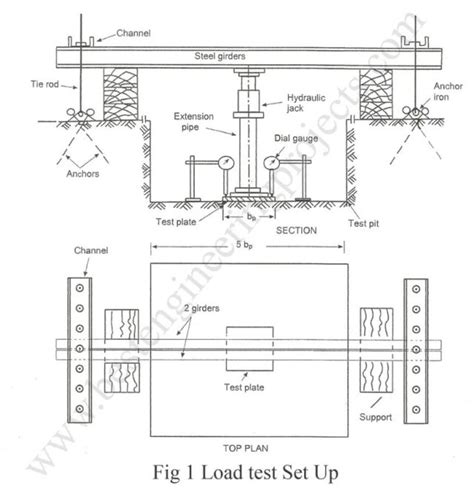

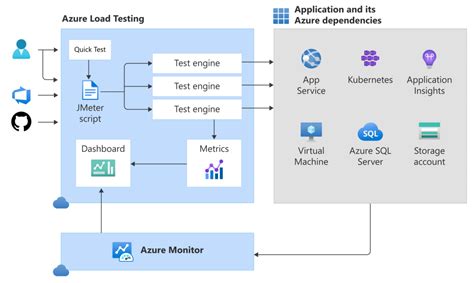

- Test Planning: Define the test objectives, scope, and requirements. Identify the system or component to be tested, the loads and stresses to be applied, and the test environment.

- Test Setup: Prepare the test setup, including the test rig, instrumentation, and data acquisition systems.

- Load Application: Apply the loads and stresses to the system or component, following the test plan and procedure.

- Data Acquisition: Collect and record data during the test, including parameters such as stress, strain, displacement, and temperature.

- Data Analysis: Analyze the data to evaluate the system's performance, identify potential failures, and determine the root cause of any issues.

Applications of Load and Shift Tests

Load and shift tests have a wide range of applications across various industries, including:

- Aerospace: Load and shift tests are used to evaluate the structural integrity and performance of aircraft and spacecraft components.

- Automotive: These tests are used to assess the durability and reliability of vehicle components, such as engines, transmissions, and suspension systems.

- Energy: Load and shift tests are used to evaluate the performance and reliability of wind turbines, solar panels, and other renewable energy systems.

- Construction: These tests are used to assess the structural integrity and performance of buildings, bridges, and other infrastructure.

Benefits of Load and Shift Tests

Load and shift tests offer numerous benefits, including:

- Improved Reliability: These tests help identify potential failures and optimize system design, ensuring improved reliability and performance.

- Reduced Maintenance: By identifying potential issues early, load and shift tests can help reduce maintenance costs and downtime.

- Enhanced Safety: These tests help ensure the safety of people and equipment by identifying potential hazards and mitigating risks.

- Increased Efficiency: Load and shift tests can help optimize system performance, reducing energy consumption and improving overall efficiency.

Best Practices for Load and Shift Tests

To ensure the accuracy and reliability of load and shift tests, follow these best practices:

- Use calibrated equipment: Ensure that all test equipment is calibrated and certified to industry standards.

- Follow test procedures: Adhere to established test procedures and protocols to ensure consistency and accuracy.

- Monitor and control test conditions: Carefully monitor and control test conditions, including temperature, humidity, and vibration.

- Analyze data carefully: Analyze data carefully to identify potential issues and optimize system design.

Conclusion

Load and shift tests are essential tools for reliability analysis, enabling engineers to assess the performance and durability of mechanical systems, structures, and components. By understanding the types, procedures, and applications of these tests, engineers can optimize system design, improve reliability, and ensure the overall safety and efficiency of the system. By following best practices and using calibrated equipment, engineers can ensure the accuracy and reliability of load and shift tests.

We encourage you to share your thoughts and experiences with load and shift tests in the comments below. How have you used these tests to improve the reliability and performance of your systems?

What is the purpose of load and shift tests?

+Load and shift tests are designed to simulate real-world operating conditions, subjecting the system or component to various loads, stresses, and environmental factors to evaluate its reliability, durability, and performance.

What are the types of load and shift tests?

+There are several types of load and shift tests, including static load test, dynamic load test, shift test, and cyclic load test.

What are the benefits of load and shift tests?

+Load and shift tests offer numerous benefits, including improved reliability, reduced maintenance, enhanced safety, and increased efficiency.