Intro

Boost efficiency and productivity in your Los Angeles, CA distribution center with these expert tips. Learn how to optimize warehouse layout, streamline inventory management, improve logistics, and enhance supply chain visibility. Discover the top 5 strategies to transform your LA distribution hub into a lean, mean, shipping machine.

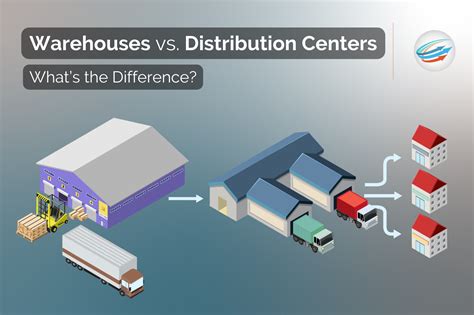

In today's fast-paced and highly competitive business landscape, optimizing your distribution center is crucial for maintaining a competitive edge. Los Angeles, being a major hub for logistics and transportation, presents a unique set of challenges and opportunities for businesses looking to streamline their distribution operations. In this article, we will explore five ways to optimize your Los Angeles, CA distribution center, ensuring that your business remains agile, efficient, and profitable.

1. Implement a Warehouse Management System (WMS)

A Warehouse Management System (WMS) is a software application that helps manage and control the day-to-day operations of a distribution center. By implementing a WMS, you can optimize your warehouse operations, improve inventory management, and increase productivity. A WMS can help you:

- Track inventory levels in real-time

- Automate tasks such as picking, packing, and shipping

- Improve order fulfillment rates

- Reduce labor costs and improve efficiency

When selecting a WMS, consider the following factors:

- Scalability: Choose a WMS that can grow with your business

- Integration: Ensure the WMS integrates with your existing systems, such as ERP and CRM

- Customization: Select a WMS that can be tailored to your specific business needs

- Support: Look for a WMS provider that offers robust customer support and training

Benefits of Implementing a WMS

- Improved inventory accuracy

- Increased productivity

- Reduced labor costs

- Improved customer satisfaction

2. Optimize Your Warehouse Layout

The layout of your warehouse can significantly impact the efficiency of your distribution center. A well-designed warehouse layout can help reduce labor costs, improve productivity, and increase storage capacity. Consider the following tips when optimizing your warehouse layout:

- Use a zone-based layout: Divide your warehouse into separate zones for receiving, storage, and shipping

- Implement a pick-to-light system: Use lights to guide pickers to the correct locations

- Use vertical storage: Maximize storage capacity by using vertical storage solutions

- Create a designated area for returns: Streamline the returns process by designating a specific area for returns processing

Benefits of Optimizing Your Warehouse Layout

- Improved productivity

- Reduced labor costs

- Increased storage capacity

- Improved customer satisfaction

3. Invest in Automation Technology

Automation technology can help streamline your distribution center operations, improve productivity, and reduce labor costs. Consider investing in the following automation technologies:

- Automated storage and retrieval systems (AS/RS)

- Conveyor systems

- Robotics

- Automated labeling and packaging systems

When selecting automation technology, consider the following factors:

- ROI: Evaluate the return on investment for each technology

- Integration: Ensure the technology integrates with your existing systems

- Maintenance: Consider the maintenance requirements for each technology

- Support: Look for technology providers that offer robust customer support and training

Benefits of Investing in Automation Technology

- Improved productivity

- Reduced labor costs

- Increased accuracy

- Improved customer satisfaction

4. Implement a Transportation Management System (TMS)

A Transportation Management System (TMS) is a software application that helps manage and optimize transportation operations. By implementing a TMS, you can improve transportation efficiency, reduce costs, and increase customer satisfaction. A TMS can help you:

- Optimize routes and schedules

- Automate freight audits and payments

- Improve carrier management

- Increase visibility and tracking

When selecting a TMS, consider the following factors:

- Scalability: Choose a TMS that can grow with your business

- Integration: Ensure the TMS integrates with your existing systems, such as ERP and CRM

- Customization: Select a TMS that can be tailored to your specific business needs

- Support: Look for a TMS provider that offers robust customer support and training

Benefits of Implementing a TMS

- Improved transportation efficiency

- Reduced costs

- Increased customer satisfaction

- Improved visibility and tracking

5. Focus on Sustainability

In today's environmentally conscious business landscape, sustainability is a key consideration for distribution centers. By implementing sustainable practices, you can reduce your environmental impact, improve your brand reputation, and attract customers who share your values. Consider the following sustainable practices:

- Use energy-efficient lighting and equipment

- Implement a recycling program

- Use eco-friendly packaging materials

- Invest in solar panels or renewable energy sources

Benefits of Focusing on Sustainability

- Improved brand reputation

- Attracting customers who share your values

- Reduced environmental impact

- Cost savings

By implementing these five strategies, you can optimize your Los Angeles, CA distribution center, improve efficiency, reduce costs, and increase customer satisfaction. Remember to stay focused on sustainability, invest in automation technology, implement a transportation management system, optimize your warehouse layout, and implement a warehouse management system.

What is a Warehouse Management System (WMS)?

+A Warehouse Management System (WMS) is a software application that helps manage and control the day-to-day operations of a distribution center.

What are the benefits of implementing a Transportation Management System (TMS)?

+The benefits of implementing a TMS include improved transportation efficiency, reduced costs, increased customer satisfaction, and improved visibility and tracking.

Why is sustainability important in distribution centers?

+Sustainability is important in distribution centers because it can help reduce environmental impact, improve brand reputation, and attract customers who share your values.

We hope this article has provided valuable insights into optimizing your Los Angeles, CA distribution center. Share your thoughts and experiences in the comments below, and don't forget to share this article with your colleagues and friends.